|

|

|

You can get e-magazine links on WhatsApp. Click here

|

|

|

|

|

|

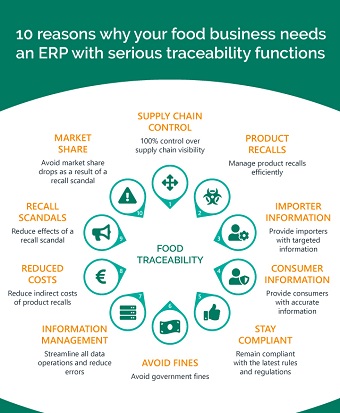

10 reasons why businesses need ERP with serious traceability functions

|

|

Thursday, 11 April, 2019, 15 : 00 PM [IST]

|

|

Dana Leahu and Floor Sloot-Wolter

|

30 million euros – That’s the cost of a recall scandal for your food company. And how can you prevent this massive loss from happening to your business? Food traceability and safety have been some of the most important recent food industry trends, pushing growers, manufacturers and distributors to adapt to the strict requirements for compliance. Food chain traceability at all stages of production is essential not only for consumer protection but also for preventing or cutting the costs of possible recalls. Moving a step forward into a worst-case scenario, recalls can destroy the image and profits of a company with one simple headline.

Do you have full visibility into your entire supply chain?

Food traceability should be the back-bone of every administrative food operation. Should be, since unfortunately many companies still keep their data in Excel files, on servers located under their desks. But by creating transparency along the supply chain, you are easily able to prove and record, for example, where the fish was caught, where the meat was sliced or where the milk comes from, and have access to all the information associated with it. This goes for manufacturers, growers, breeders and producers – they all have to look one step forwards and one step backwards into every instance and be able to identify the source of all food input. This way, a food company can take all measures at the right time and reactively implement actions correctly and safely. Especially for meat companies that deal with freezing, cooling and thawing. How does your food company comply?

Product recalls – biggest threat to profitability

When a product is discovered as posing safety issues or defects that might become a danger to the consumer, a request of return is issues. This request of return can put the food manufacturers and distribution companies face to face with legal action, as well as the costly consequences when dealing with the maintenance of their corporate image as anything but negligent. Mislabelling, undeclared allergens, foreign matter, tampering can lead to microbial contamination such as Salmonella (the leading cause for food recalls). Food industries with the most risks of product recalls due to bacterial infections are prepared foods, baked foods and fresh produce but also dairy.

Food safety regulations

Food regulation and legislations are demanding full transparency and traceability into all food business processes. An ERP implementation can prevent challenges such as food safety problems, supply chain issues and matters regarding traceability features. However, many businesses remain biased towards investing in a food traceability strategy, while they could very fail by their ability to track this data.

The EU has one of the highest food safety standards in the world. The set of legislation in place, combined in The General Food Law, ensures that food is safe for consumers.

The General Food Law Regulations demand the ability to trace and follow food and feed through all stages of production, processing and distribution. Food or feed that is not in compliance with the food safety requirements must either not be distributed among the food chain or be recalled.

For quick exchange of information about food safety recalls among the EU members, an alert system has been put in place. RASFF, the Rapid Alert System for Food and Feed is the key tool to ensure the flow of information when risks to public health are detected.

Quality Standards provide a framework for effectively managing your organisation's food safety responsibilities. BRC, IFS, FSSC22000 are recognised standards for auditing food manufacturers with a focus on food safety and the quality of processes and products. These Quality Standards demand that a food product can be tracked and traced within four hours during an audit.

In order to do a full track & trace in four hours you need a good system in place to have full visibility. This is where the function of an ERP system can help. The ERP system has all the information needed for traceability demands at hand. The lot numbers of raw materials are digitally linked to Bills of Materials and production orders. The lot numbers of the semi-final products and consumer products are also linked to these production orders. This way you can follow and link products throughout your production system. In addition, all registered quality checks are linked to the lot information. This gives you full visibility to do, within the required four hours, a full traceability check.

Food traceability as an essential function

Food traceability technology is here to help out every food producer and manufacturer remain compliant and streamline their processes with complete transparency in mind. By creating a linked tracking flow of events, food traceability software can give you a real-time visualisation of your entire supply chain at batch-lot level.

Does your food business offer full inventory traceability? Do you have an overview and access to all the layers of data that you need, right now, to successfully manage every area of your business?

Worries about changing ingredient prices or spoilage in the warehouse can prevent you from growing your business the way you want to. Considering the costs of food manufacturing mistakes, companies often find it hard to focus on a strategy that involves food safety.

(Dana is Online marketer,Foodware 365,a company known for managing food traceability, quality control and Floor is Food safety expert)

|

|

|

|

|

|

|

|

|

|