|

|

|

You can get e-magazine links on WhatsApp. Click here

|

|

|

|

|

|

In industrial refrigeration, growth driven by CO2 transcritical systems

|

|

Thursday, 20 November, 2025, 08 : 00 AM [IST]

|

|

Dr Priyanka Kale & Dr Ganesh Gaikwad

|

Refrigeration is the process of removing heat from an enclosed space to lower its temperature and is used for applications like food preservation and air conditioning. This is achieved through a refrigeration cycle, which involves the compression and expansion of a refrigerant fluid, causing it to change between a liquid and gas state to transfer heat from a cold area to a warmer one. The main components of this system are the compressor, condenser, expansion valve, and evaporator. Future trends in refrigeration focus on sustainability and advanced technology, driven by a move towards eco-friendly natural refrigerants and greater energy efficiency. Key developments include the integration of the Internet of Things (IoT) for predictive maintenance and remote monitoring, the adoption of AI and automation, and the commercialisation of innovative technologies like magnetic refrigeration. Smart features, energy saving innovations, and customisable designs are also shaping the future of both commercial and consumer refrigeration.

Sustainability and energy efficiency

• Natural and low-GWP refrigerants : Traditional refrigerants with high global warming potential are being phased out in favour of natural options like ammonia and CO2 or newer synthetic fluids like hydrofluoroolefins (HFOs).

• Increased energy efficiency: New systems use variable speed compressors to match cooling demand, adaptive defrost systems, and heat recovery technologies.

• Renewable energy integration: Hybrid systems that combine conventional refrigeration with solar or wind energy are becoming more common.

Smart technology and automation

• IoT and smart sensors: Connected devices provide real-time data on temperature, humidity, and system performance, enabling predictive maintenance and remote management to prevent downtime.

• AI and machine learning: These technologies analyse data to optimise energy consumption, automate processes, and identify potential issues before they cause failures.

• Robotics and automation: Automation is transforming industrial refrigeration by improving efficiency and safety.

Advanced and innovative technologies

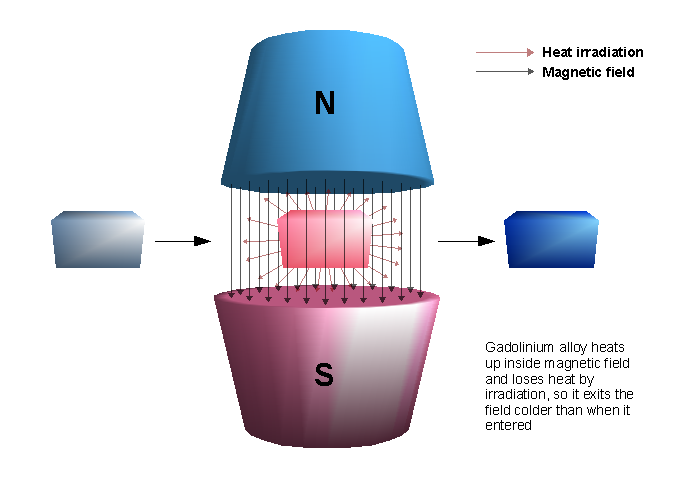

• Magnetic refrigeration: This is a potentially revolutionary technology that is more energy-efficient and eliminates the need for traditional refrigerants.

• Modular and scalable designs: Flexible, modular systems allow businesses to expand or service units without shutting down entire operations.

• Block chain: This technology is being explored to increase transparency and traceability within the cold chain, particularly for tracking the movement and temperature of perishable goods.

Consumer-focused innovations

• Customisable interiors: Refrigerators are becoming more flexible with features like adjustable shelves, pull-out drawers, and specific temperature-controlled zones to keep food fresh for longer.

• Larger capacity and multi-door configurations: Larger units and new configurations, such as four-door models and large-capacity French door refrigerators, are gaining popularity for convenience and storage.

• Advanced features: Common features include humidity-controlled drawers, fingerprint-resistant surfaces, and high-quality ice makers.

Major Future Trends

1. Next-Gen Cooling Technologies

Alternative cooling approaches beyond the standard vapour-compression cycle are emerging. For example, research into magnetocaloric materials (where a magnetic field drives cooling) is advancing. One study pointed to thermogalvanic cooling, where chemical reactions generate cooling power, as a potentially lower-carbon replacement for standard fridge technology. Over time, as these mature, we may see refrigerators, cold-rooms and other cooling systems that are quieter, less reliant on high-GWP refrigerants, more compact, and potentially more efficient.

2. Smart, Predictive & Digitalised Refrigeration

The monitoring/analytics/IoT market for refrigeration is growing fast: for example, the “refrigeration monitoring” segment is expected to grow to ~US$17 billion by 2030 at ~8.7% CAGR. Features include: real-time temperature/condition monitoring, remote control, AI algorithms predicting failures, “digital twin” models of the refrigeration system. For operators (retail, cold-chain, food-logistics) this means less reactive maintenance, lower downtime/spoilage, better energy optimisation. For manufacturers, it means new business models (service contracts, data-driven upgrades).

3. Natural/Low-GWP Refrigerants & Sustainability Compliance

The transition away from high-GWP HFCs/HCFCs to natural refrigerants (CO2, ammonia, hydrocarbons) and HFO blends is accelerating. For example: in the industrial refrigeration market, growth is being driven by CO2 transcritical systems and low-charge ammonia. Regulatory pressure (phase-outs, quotas, energy-labels) is a strong driver. Future refrigeration systems will need to be “refrigerant-ready” for natural/low-GWP options. Designs will increasingly factor in safety (flammability, high pressure), lifecycle costs, and environmental impact.

4. Energy Efficiency, Heat Recovery & Integration with Renewables

Efficiency improvements remain key: variable-speed compressors, improved heat exchangers, better insulation, modular designs. Heat recovery will become more common: waste heat from refrigeration can be reused (water-heating, space heating) improving overall plant efficiency. Integration with renewable energy (solar, wind) and smart grid/energy-storage solutions is emerging. For example, load-shifting research shows up to ~20% energy savings possible in compressor sequencing. Refrigeration systems will increasingly not just “cool” but be part of overall energy-systems in buildings/industrial sites. For example, a cold-storage warehouse powered partly by rooftop solar, with heat-recovery to serve auxiliary loads.

5. Modular, Flexible & Scalable Cold-Chain / Logistics & Off-Grid Solutions

With the growth of e-commerce, fresh-food delivery, pharmaceuticals and cold-chain logistics, the demand for scalable, modular refrigeration units is rising. In emerging markets (e.g., rural or semi-urban in India), off-grid or hybrid systems (solar + battery + refrigeration) will become more common. For companies setting up new cold-storage or logistics operations, focus will shift to modular units that can scale (add capacity easily), can operate in variable power/ambient conditions, and can be part of a distributed network rather than a single massive plant.

Market Growth & Regional Opportunities

The global commercial refrigeration equipment market is forecast to grow to ~US$60.1 billion by 2030 (from ~US$44.9 billion in 2025) at ~6% CAGR. In India, the household refrigerator market is projected to reach US$8.92 billion by 2030 (from ~US$5.63 billion in 2025) at ~9.63% CAGR. Cold-chain infrastructure in India (and other emerging markets) is witnessing strong push– e.g., government incentives for rural electrification, cold-storage grants. If you are looking at business/industry opportunities (manufacturing, service, logistics) in places like Pune/Maharashtra/India, the growth potential is high but also competitive. Being early with “future-ready” systems (digital + natural refrigerants + modular) may give a differentiator.

Challenges & Considerations for the Future

New technologies (magnetocaloric, thermogalvanic) are promising but are not yet mainstream commercial viability, safety, cost are still to be fully proven. Training and skills: Operating advanced refrigeration (natural refrigerants, digital systems) requires skilled technicians a potential bottleneck in some regions. Regulatory/regime complexity: As new refrigerants and system types become common, safety standards, codes, servicing frameworks will evolve compliance risk. Materials (e.g., copper, speciality compressors), regulatory changes, and refurnished infrastructure all affect cost. As systems become more connected/IoT enabled, cyber security, data privacy, system reliability become important.

(Kale is assistant professor, MIT College of Food Technology, Chhatrapati Sambhajinagar; Gaikwad is assistant professor, School of Food Technology, MIT Art, Design and Technology University, Pune. They can be reached at priyankakale665@gmail.com)

|

|

|

|

|

|

|

|

|

|