|

|

|

You can get e-magazine links on WhatsApp. Click here

|

|

|

|

|

|

Economically, higher value attached to cashewnuts vis-a-vis cashew apples

|

|

Tuesday, 18 April, 2017, 08 : 00 AM [IST]

|

|

Dr Soumitra Banerjee

|

Introduction

Cashew (Anacardium occidentale) tree is a tropical evergreen that starts fruit bearing after 3-4 years of plantation. As fruit, cashew tree produces cashew apple and cashew nut. Cashew apple is considered as pseudo fruit whereas the nut enclosed with a hard shell is the fruit. Cashew nut kernel is considered as nutritious and delicious which is consumed widely around the world (Azam-Ali and Judge, 2001). Compositional profile of cashew nut as reported by Akinhanmi et al. (2008) is moisture 7.2%, ash 2.8%, crude fat 49.1%, crude protein 36.3%, crude fibre 3.2% and carbohydrate 1.4%. It was further reported that cashew kernel contains minerals like potassium, calcium, magnesium, sodium and phosphorus though zinc and iron was found in low concentration.

Nandi (1998) referred cashew nuts as highly nutritious which has pleasant and highly acceptable sensory profile that is consumed as raw or fried or in some other form. Economically cashew nuts are given more importance than the cashew apples. Objective of this review article is to educate the reader about cashew nut processing aspects, byproduct utilisation and various value-added products developed from cashew kernels as well as from cashew apples.

Cashewnut processing

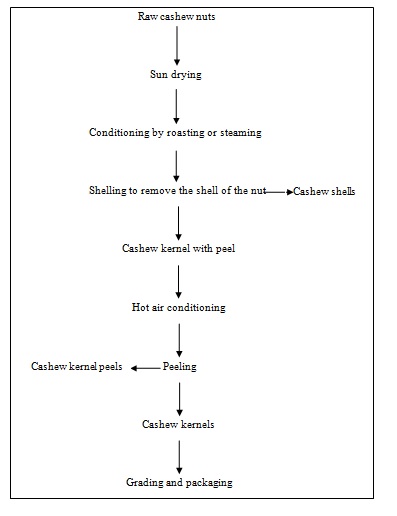

The main aim of cashew nut processing is to extract the valuable, highly nutritious and delicious cashew kernel from the nut without damaging the kernel. Cashew nuts obtained from cashew tree after harvesting are sun dried for partially drying the nuts before storage. After sun drying, the nuts become ready for processing which include a number of unit operations like conditioning, roasting, shelling, drying, peeling, grading and packaging (Banerjee and Shrivastava, 2014). The processing steps of cashew nut are shown in Fig. 1.

Fig. 1: Cashew nut processing flow chart (Azam-Ali and Judge, 2001 and Mohod et al. 2011)

Byproducts obtained after cashewnut processing

Cashew shells

After processing of cashew nuts, edible white cashew kernels are obtained along with shells and peels, which may be considered as waste products generated after cashew nut processing. Earlier day’s cashew shells were thrown away or were used as fuel source, since cashew nut shells contain cashew nut shell liquid (CNSL) oil. The oil is dark in colour and viscous in nature that contains anacardic acid (80.9%) and cardol (10-15%) along with some other minor material components.

Nowadays CNSL found its applications in many versatile areas. Some industrial applications of CNSL are listed below (Jeyalakshmi 2015 and CEPCI 2017): Paints and enamels; Electrical insulation varnish; Polymer; Lamination; Rubber products; Adhesive; and Pesticide action.

CNSL is toxic and corrosive to human skin and prolonged use may cause skin disease (Akinhanmi et al. 2008). In a research study, defatted cashew shells, i.e. the shells obtained after extraction of CNSL, were used in extraction of starch that have applicability as renewable polymeric material (Yuliana et al. 2012).

Cashew kernel peels (Testa)

Cashew peels are rich in protein and dietary fibre that may be used for cattle feed (Donkoh et al. 2012). Work had been reported on production of tannase by Aspergillus niger CEPC 11 (MTCC 5898) for cashew testa peel (Viswanath et al. 2016).

Value-added cashewnut products

The US Department of Agriculture (USDA) has defined value-added products thus; the production of product with desirable changes in properties and enhancement of value of the final product (University of Maryland-Extension, 2013). Need for value addition for cashew kernels was emphasised by few published reports as a means to enhance and expand the market demand. (Nseha, 2016 and Magboo, 1998). Various value-added products have been developed from edible cashew kernels which would be discussed in this section. Value addition of cashew kernels would increase the consumer’s acceptability, market demand and desirable properties of cashew kernels.

Roasted (salted) cashew kernels

Raw cashew kernels are roasted in low flame with little oil addition with continuous stirring. One must be careful and uniform stirring must be done to prevent over roasting or burning. Burnt cashew kernels would taste bitter. Once the nuts turn golden yellow, brine solution is to be sprayed once or twice followed by stirring. Hot salt coated kernels to be taken down from the flame and cooled for 15-20 min before consumption (Behr, 2014).

Sugar-coated cashew kernels

Raw cashew kernels are taken and heated for 10 min with continuous stirring to get dry mild roasted kernels. Hot and thick sugar syrup is poured over the dry roasted cashew kernels with stirring, so that the syrup gets spread uniformly and gets coated all over the kernel surface. Heating to be continued with stirring for some more time and kernels sticking to each other need to be separated. After that the thick sugar syrup with kernels is to be allowed to cool and the sugar syrup solidifies on the surface of the kernels (Prakash, 2015).

Cashew butter

Cashew butter is nutritious as it is a rich source of vitamins, lipids and protein. It may be used as a food spread and has rich and creamy sensory profile. As it contains high amount of lipid, cashew butter is recommended to be stored at a cool and dark place to prevent rancidity defect (Kumar 2011 and Cespedes 2010).

Cashewnut paste

Cashewnut kernels are soaked in drinking water or milk till the kernels become soft. After that the kernels are ground to form a smooth paste. During grinding, if required a small amount of water may be added. The formed paste is to be stored in low temperature refrigeration for long time storage. This paste may be used while preparing various types of vegetable dishes or sweet dish preparations to experience enhanced flavour experience (Dalal, 2017).

Other cashewnut kernel products

Kerala State Cashew Development Corporation Limited (KSCDC) under Government of Kerala, has worked extensively in the field of development of cashew kernel value-added products. Value-added products developed and marketed are following: Cashew Vita – Nutritious health drink; Cashew soup mix; Milky kaju; Choco kaju; and Cashew powder.

Value-added products from cashew apples

Cashew apple is not considered as a real fruit so it is called pseudo fruit. It is rich source of vitamin C, sugars, phenolic compounds, tannins and various other elements like potassium, calcium, magnesium, phosphorus, sodium and so on (Lowor et al. 2009). Cashew fruits are nutritionally rich but still their potential has not been much explored. This section of the article would describe the various products developed from cashew apples:

Cashew apple juice

Fresh and cleaned cashew apples were grated and juice was extracted using mechanical screw press. Obtained juice was recommended to be pasteurised (95°C for 7 min) in combination with preservatives, i.e. sorbic and benzoic acids, for longer period storage (Kabuo et al. 2015).

Cashew wine

Cashew apple juice is extracted and fermented with wine yeast (Saccharomyces cerevisiae – var ellipsoideus). Fermentation is done for two weeks followed by filtration to get filtered wine, which after pasteurisation is stored for six months for ageing. Aged wine after clarification - It is packaged and stored away from direct sunlight. Cashew wine contains 6-12% alcohol and is a light yellowish colour liquid, which is popular in some parts of Asian and Latin American countries (Azam-Ali and Judge, 2001).

Cashew feni

In Goa (India), cashew juice is utilised for preparation of alcoholic beverage named as Fenny (Azam-Ali and Judge, 2001).

Dried cashew fruit

Cashew fruits are collected from the farm, and then they are boiled in brine solution to reduce the astringency taste. Then the fruit is dried followed by packaging and storage (Suganya & Dharshini, 2011).

Cashew syrup

For preparation of cashew syrup, first stage was to remove the astringency taste by following the same boiling method as done for dried cashew fruit preparation. Then sugar, citric acid and sodium benzoate needed to be added followed by mixing for 3-4 hours. Prepared syrup is to be cleaned and packaged (Suganya & Dharshini, 2011).

Conclusion

Cashew trees grow well in tropical climatic regions of the world. Cashew nut processing facilities mainly focus on extraction of the kernel from the cashew nut. These kernels are packaged and are sold in the market. Now-a-days to survive in the competitive market, it is a challenging task to continue with the same product-cashew kernel; instead it may become quite profitable to introduce value-added cashew kernel products. After processing of cashew nuts, the byproducts, i.e. shells and peels, could be processed to get products of industrial demands. Beside this, the cashew apple which is generally neglected contains rich nutritive profile. Cashew apple may be utilised to develop various products starting from wine to syrup. India being leader of cashew nut processing, has a great scope to work more in the field of value addition. Many works have already been done but commercialisation of developed processes needs to be addressed. More emphasis needed to be given for cashew plantation, processing and value-added product development.

[The author is assistant professor, Centre for Incubation, Innovation Research and Consultancy (CIIRC), Jyothy Institute of Technology. He can be contacted at soumitra.banerjee7@gmail.com.]

|

|

|

|

|

|

|

|

|

|