|

|

|

You can get e-magazine links on WhatsApp. Click here

|

|

|

|

|

|

Innovated industrial method of ghee making at Panchmahal Dairy, Gujarat

|

|

Saturday, 04 February, 2006, 08 : 00 AM [IST]

|

|

R S Patel*, L J Patel, S A Sheth and A Saxena

|

Ghee occupies a very significant place in Indian diet. The reference of ghee dates back to Vedic times in ancient India. Over and above its dietary use, ghee is an indispensable part of religious and ceremonial rites Ghee occupies a very significant place in Indian diet. The reference of ghee dates back to Vedic times in ancient India. Over and above its dietary use, ghee is an indispensable part of religious and ceremonial rites

Traditionally ghee is made first by converting milk into dahi, churning the dahi at room temperature to yield traditional deshi makkhan or butter, clarifying the traditional butter after some period of storage and conversion into ghee by boiling it continuously at temperatures up to 115-120 C depending upon regional preferences. Making ghee in the presence of milk proteins yields high levels of conjugated linoleic acids which are known to be anti-carcinogenic agents. Ghee made traditionally contains as high at 5 times CLAs as compared to original milk fat in milk. CLAs are also known to be anti-oxidants which are responsible for higher shelf life of ghee at ambient temperatures (Aneja, 1991).

Nowadays life has become very fast and a lot of transformation is taking place worldwide. The post-WTO situation presents a big challenge to our current dairy industry where competitiveness with global market has become unavoidable. Although ghee is our indigenous product, it has to meet international standard with respect to aflatoxin, heavy metals, pathogens, pesticide residues, ghee residues, etc. For that innovative and cost effective methods have to be developed.

Current methodoloy of ghee manufacture:

For the manufacture of ghee there are several methods. However, 90 per cent of the ghee produced in the country is made by traditional methods. Increased awareness about energy management has led to the development of energy efficient and continuous methods. (Punjrath, 1974) for ghee manufacture, which include either an oil separator (Bhatia, 1978) to separate serum and fat phase or use of scrapped surface heat exchangers (Abhichandani, et al., 1995). Both the processes save energy and yield a comparable product. Use of microwaves for ghee making has also been reported (Sahai, 1996). The ghee so prepared had higher vitamin A and E contents and appreciably lower levels of cholesterol.

The different methods of ghee manufacture are the desi or indigenous or traditional method, creamery - butter method, direct cream method, pre-stratification method and continuous method.

Continuous method of ghee making:

Dairy plants have tried to modify, scale-up and adopt the traditional batch process for commercial production. Although large quantities of ghee are made by this process, there is a long felt need of a continuous plant. One of the ways is to adopt the established process for producing butter oil involving centrifugal separation of moisture followed by final dehydration under vacuum.

As an alternative to such a system, a scrapped surface falling film heat exchanger along with auxiliary equipment such as a melting vat and mechanical clarifier has been developed to serve as a continuous ghee making plant.

Various approaches made for continuous ghee making are due to the following salient features of the process viz. (1) very high heat transfer coefficient and hence compact design (2) better control on quality of product (3) only small hold-up of raw material in the plant at any time and hence no changes of whole batch getting spoiled (4) no spillage loss (5) simple, robust and hygienic design (6) minimum strain on the operator (7) can be cleaned in place (8) high degree of automation possible (9) no surface fouling and hence heat transfer coefficient can be maintained throughout the run of the system (10) easy capacity control (11) no foaming problem. Cream can be handled conveniently and (12) economic operation.

Improved methodology developed by Panchmahal Dairy

Under Total Quality Management Programme at Panchmahal Dairy, Godhra, an innovated method of ghee manufacture commercially was undertaken. For that a Small Group Activity (SGA) team was constituted which would work on the improvement in procedure of ghee making with a special focus on reducing fat and SNF losses from the largest section of the dairy which handles costliest ingredient of milk, i.e. milk fat.

First, data analysis was done to identify the losses areas, which occurred in ghee manufacture on a big scale. A brainstorming session was conducted on saving the serum solids since fermentation of milk was not carried out and only sweet serum separated out of the stratification tank. It was decided that a modification in normal procedure has to be done to recover fat and SNF from sweet serum. To collect fat and SNF from serum, a serum separator was suggested for melted fresh white butter so that SNF can be directly used with market milk in standardisation and fat per cent of butter be increased and sent to butter melting vat and Primary Settling tank (PST) and thereafter to ghee kettle.

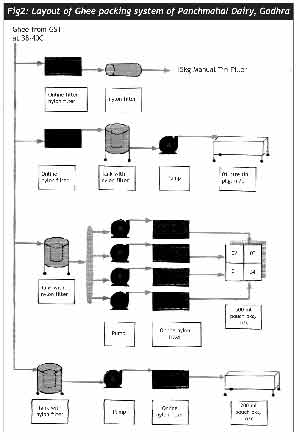

The procedure was finalised with the inclusion of a serum separator and a spiro-heater in the process. The details of which are shown in the flow diagram and block diagram. (Fig.1, Fig.2 and Fig.3)

Ghee manufacturing process at Panchmahal Dairy

At first, fresh raw milk is received at the raw milk receiving dock (RMRD) of the main dairy plant, chilled and stored. This milk is subjected to cream separation after necessary filtration and warming to 55-60 C in the regeneration section of the pasteurizer. Resultant cream is pasteurized in a high temperature short time (HTST) plant at 90-92 C, chilled to 10-12 C and stored in insulated, jacketed, cream storage tanks. This cream is then pumped to the Continuous Butter Making Machine (CBMM) wherein white butter is obtained. Resultant buttermilk along with serum from serum separator is chilled in a plate chiller and diverted for use in standardization of fresh milk.

The white butter is now pumped via screw conveyor to the spiro-heater wherein white butter is melted by providing heat indirectly by hot water. This melted butter is now conveyed to melted butter tanks with agitator and hot water circulation jacket from where it is subjected to serum separation wherein serum is separated, chilled in a plate chiller and pooled with sweet buttermilk for use in milk standardisation. The melted butter with low moisture and high fat and serum

|

|

|

|

|

|

|

|

|

|